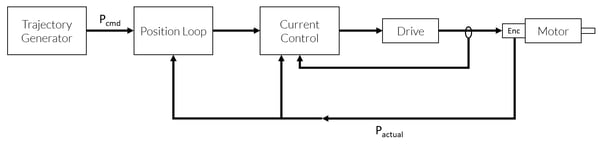

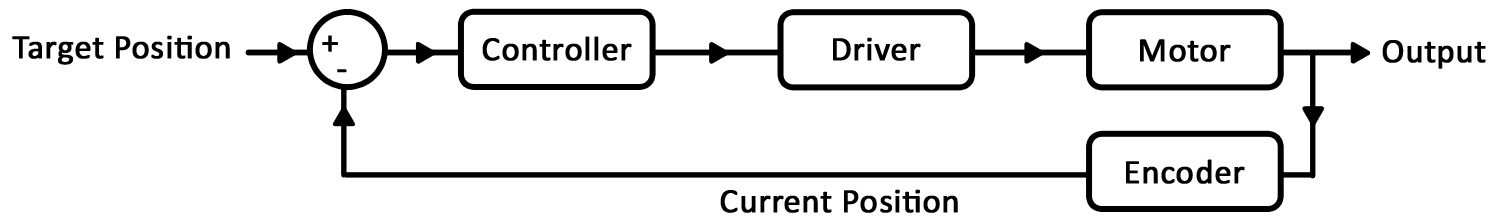

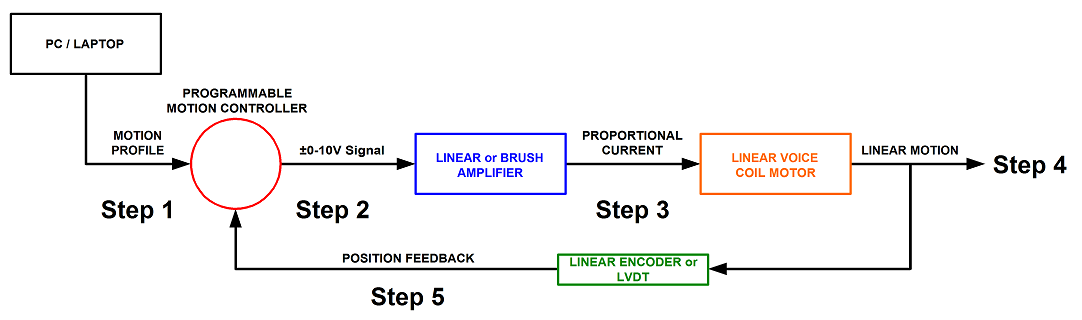

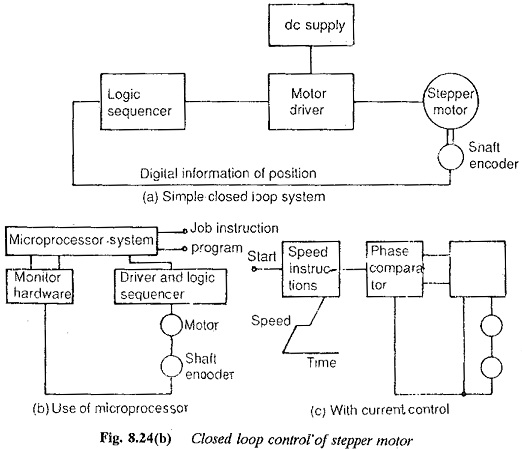

Closed loop step motor the encoder is used as a feedback source in a position loop which adjusts the torque requirements in real time.

Closed loop current control stepper motor.

Small form factor efficient and protected power stag with fault feedback advanced digital processing for smooth and accurate closed loop control accurate angle and current feedback sense for high resolution micro stepping.

Closed loop stepper drive systems often require.

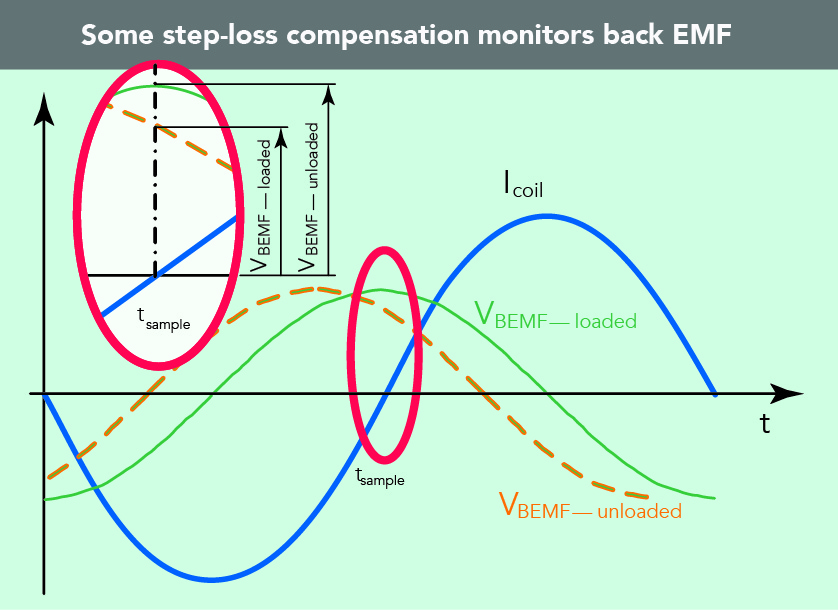

The rotor position detection sensor monitors the rotation speed and amount.

Closed loop stepper systems supply the motor with just enough current to control the load and this results in much less audible noise than open loop setups.

Closed loop stepper motor performance αstep these stepper motors use our alphastep closed loop technology to maintain positioning operation even during abrupt load fluctuations and accelerations without hunting or gain tuning.

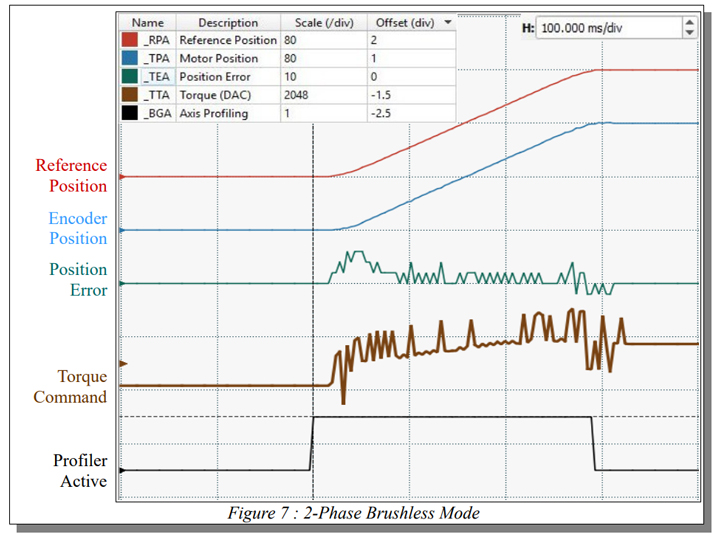

The most advanced closed loop stepper control method is to operate the motor as a two phase brushless bldc motor.

Under normal circumstances the operation of the motor is monitored and control is applied using open loop like a standard stepper motor.

If an error occurs between the command and motor position due to a load or the like the system immediately switches to closed loop control like a servo motor.

Common names for this architecture include closed loop stepper control or servo stepper.